Tesla repair scanning, using advanced diagnostic tools linked to onboard computers, revolutionizes bodywork services for electric and hybrid vehicles like Mercedes Benz. This technology facilitates swift, precise analysis of intricate electrical systems, enhancing safety by early issue detection. As EV popularity grows, mastering Tesla repair scanning becomes crucial for auto body shops to provide efficient maintenance and extend vehicle lifespans through proactive problem-solving.

Tesla repair scanning is revolutionizing the way we maintain hybrid and electric vehicles. With advanced technology, professionals can now perform comprehensive checks on these complex systems, ensuring optimal performance and safety. This article delves into the world of Tesla repair scanning, exploring its benefits, key strategies, and how it’s transforming the automotive industry. From understanding the technology to executing effective component checks, this guide offers valuable insights for anyone interested in maximizing Tesla vehicle health.

- Understanding Tesla Repair Scanning Technology

- Benefits of Scanning for Hybrid/Electric Components

- Effective Strategies for Comprehensive Checks

Understanding Tesla Repair Scanning Technology

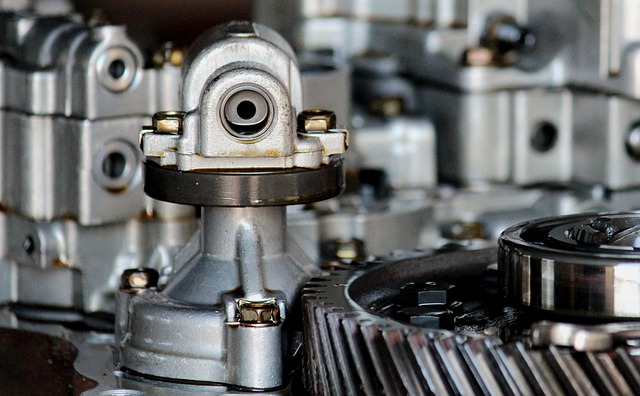

Tesla repair scanning technology has revolutionized the way electric and hybrid vehicles are diagnosed and repaired. Unlike traditional methods that rely heavily on manual inspections and guesswork, Tesla repair scanning involves advanced diagnostic tools that connect directly to a vehicle’s onboard computer. This process allows for a comprehensive analysis of intricate electrical systems, including battery packs, motor controllers, and power electronics. By leveraging this technology, auto body shops offering car bodywork services can detect even the slightest anomalies or performance issues with precision and speed.

For instance, when it comes to Mercedes Benz repair—a brand known for its cutting-edge technology—the ability to perform Tesla repair scanning ensures that every component is checked accurately. This not only facilitates faster repairs but also enhances safety by preventing potential failures that could impact the vehicle’s overall performance and efficiency. As electric vehicles continue to gain popularity, understanding and implementing Tesla repair scanning in auto body shop services becomes increasingly vital for maintaining these advanced vehicles effectively.

Benefits of Scanning for Hybrid/Electric Components

In today’s digital era, Tesla repair scanning has become an indispensable tool for servicing hybrid and electric vehicles (EVs). This advanced technology offers numerous benefits, ensuring that every component is accurately diagnosed and repaired. By employing sophisticated sensors and software, technicians can swiftly identify issues with EV systems, ranging from battery packs to motors, without the need for extensive manual inspections.

One of the key advantages is the precision it brings to the table, significantly reducing the risk of misdiagnosis. Moreover, scanning allows for a comprehensive overview of the vehicle’s health, enabling auto maintenance professionals to catch potential problems early on. This proactive approach not only saves time and money for both repair shops and Tesla owners but also contributes to extending the lifespan of these sophisticated vehicles. It’s worth noting that regular scanning can detect subtle anomalies in auto glass repair, vehicle dent repair, or other cosmetic issues, ensuring the overall well-being of hybrid and electric cars.

Effective Strategies for Comprehensive Checks

For Tesla repair scanning to be truly comprehensive, a systematic approach is key. Start by performing initial visual inspections, noting any visible damage or discrepancies. This step is crucial as it helps identify potential issues that might not be immediately apparent through digital means. Subsequently, utilize advanced diagnostic tools tailored for hybrid and electric vehicles. These tools facilitate the detection of anomalies in power electronics, motor control units, and battery systems—components critical for these vehicle types.

Integrate various testing methods to ensure thoroughness. This includes functional testing, where components are checked for performance, and diagnostic scanning that uncovers any error codes or communication issues within the vehicle’s network. Moreover, consider the integration of frame straightening and auto painting services in your checkup process. Accurate alignment ensures structural integrity while a meticulous repaint job maintains aesthetic appeal, both vital aspects of a complete Tesla repair.

Tesla repair scanning technology plays a pivotal role in ensuring the reliable operation of hybrid and electric vehicles. By employing advanced diagnostic tools, technicians can efficiently detect and address issues related to these complex components. The benefits are clear: faster troubleshooting, reduced repair times, and enhanced customer satisfaction. With strategic approaches for comprehensive checks, workshops can stay ahead in the game of electric vehicle maintenance, positioning themselves as leaders in Tesla repair scanning services.