Tesla repair scanning leverages advanced software, sensors, and cameras to perform digital inspections of electric vehicles, ensuring precision repairs that meet manufacturer specs. This technology facilitates accurate diagnostics, improves workflow efficiency, and enhances vehicle performance and safety, though initial costs and updates may pose challenges for smaller shops.

Tesla repair scanning is transforming the way electric vehicle (EV) maintenance is performed. By utilizing advanced technology, scanners ensure that repairs meet manufacturer specifications, crucial for optimal performance and safety. This article delves into the workings of Tesla repair scanning, its role in adhering to stringent standards, and explores the benefits and challenges of transitioning to digital repair compliance. Understanding these aspects offers valuable insights into the future of EV maintenance.

- Understanding Tesla Repair Scanning Technology

- The Role of Scanners in Adhering to Manufacturer Standards

- Benefits and Challenges of Digital Repair Compliance

Understanding Tesla Repair Scanning Technology

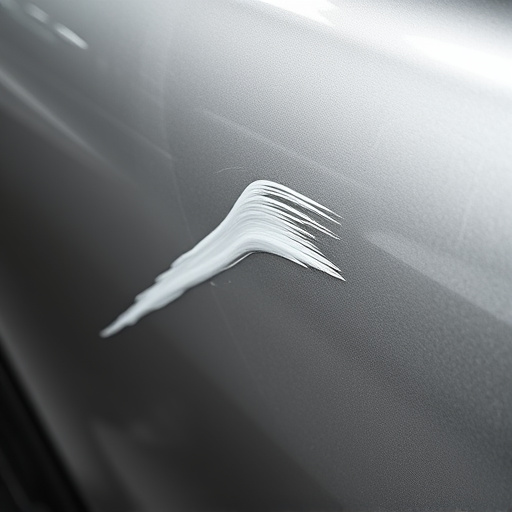

Tesla repair scanning technology has revolutionized the way auto collision centers and luxury vehicle repair shops service electric vehicles. This advanced system utilizes sophisticated software to perform a comprehensive digital inspection of Tesla vehicles, ensuring every component adheres to manufacturer specifications. By integrating high-resolution sensors and cameras, the process captures detailed images and data, providing an in-depth analysis of the car’s condition.

This innovative approach offers several advantages over traditional manual inspections. It enables auto body shops to identify even the slightest deviations from original equipment manufacturing (OEM) standards, promoting precise repairs. With real-time feedback, technicians can make informed decisions, enhancing overall repair quality. Moreover, Tesla repair scanning streamlines the process, reducing time and potential human error, ensuring customers receive top-tier service for their electric vehicles at reputable auto collision centers or luxury vehicle repair shops.

The Role of Scanners in Adhering to Manufacturer Standards

In the realm of Tesla repair and maintenance, scanners play a pivotal role in ensuring compliance with manufacturer specifications. These advanced tools are designed to accurately diagnose and identify issues within a vehicle’s intricate systems, enabling technicians to make precise repairs that adhere to the highest standards set by Tesla. By utilizing car repair services that incorporate Tesla repair scanning, workshops can achieve remarkable levels of accuracy and efficiency.

Scanners provide detailed insights into a Tesla’s electrical and software components, allowing for comprehensive assessments of both physical and digital systems. This data is crucial for performing effective automotive repair services or meticulous car restoration work. Through continuous updates and access to the latest manufacturer information, scanners ensure that repairs meet not just standard industry practices but also the precise requirements set by the original equipment maker, thereby guaranteeing optimal performance and safety for Tesla owners.

Benefits and Challenges of Digital Repair Compliance

The advent of Tesla repair scanning has revolutionized the way automotive restoration is approached, bringing about numerous benefits for both manufacturers and consumers. By digitizing the repair process, shops can access real-time data and precise manufacturer specifications, ensuring every fix adheres to the highest standards. This technology allows for accurate diagnostics, precise part replacements, and a more efficient workflow, ultimately leading to improved vehicle performance and safety.

Despite these advantages, challenges persist in implementing digital repair compliance. For smaller collision repair shops or auto repair near me, the initial investment in scanning tools can be significant. Additionally, staying up-to-date with ever-evolving software updates and maintaining data security are ongoing concerns. However, as technology advances, many of these hurdles are being addressed, making Tesla repair scanning an increasingly viable and necessary component of modern automotive servicing.

Tesla repair scanning technology plays a pivotal role in ensuring that vehicle repairs meet manufacturer specifications. By utilizing advanced scanners, workshops can accurately diagnose issues, access the latest software updates, and maintain compliance with Tesla’s rigorous standards. This digital approach not only streamlines the repair process but also guarantees the longevity and safety of Tesla vehicles. However, embracing these innovations comes with challenges, including the need for specialized training and investment in compatible equipment. As the electric vehicle market continues to grow, mastering Tesla repair scanning will become essential for garages aiming to provide top-tier services while staying ahead in a competitive landscape.