Tesla repair scanning is a game-changing technology that leverages advanced equipment like high-resolution cameras and 3D sensors to perform meticulous digital inspections of vehicles, especially Tesla models. This process allows bodyshops to detect even the smallest deviations from manufacturer standards in bodywork, panel gaps, paint accuracy, and structural integrity, ensuring consistent quality repairs. By implementing Tesla repair scanning, auto body shops can streamline their workflows, maintain high customer satisfaction, and stay aligned with modern automotive standards. Best practices include proper training, equipment calibration, and fostering a culture of continuous learning to maximize the benefits of this cutting-edge technology.

Tesla repair scanning is transforming post-repair quality control, ensuring precision and consistency. This advanced technology allows for a detailed analysis of vehicle repairs, identifying potential issues before they become problems. In this article, we’ll explore the technical intricacies of Tesla repair scanning from a professional perspective. We’ll delve into its crucial role in enhancing post-repair quality, highlighting benefits, best practices, and real-world applications, ultimately emphasizing why it’s an indispensable tool for maintaining top-tier vehicle performance.

- Understanding Tesla Repair Scanning: A Technical Perspective

- The Role of Scanning in Post-Repair Quality Control

- Benefits and Best Practices for Implementing Tesla Repair Scanning

Understanding Tesla Repair Scanning: A Technical Perspective

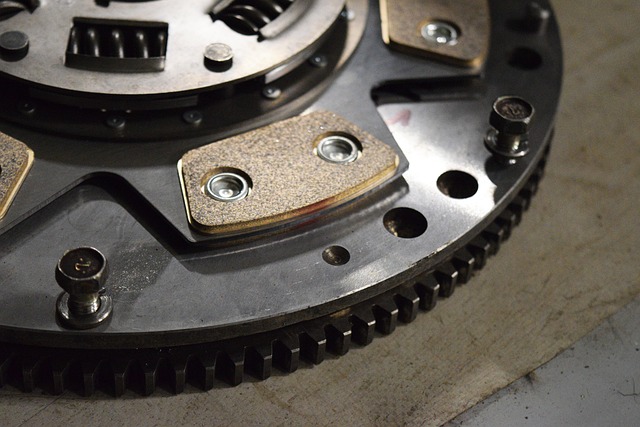

Tesla repair scanning is a sophisticated process that leverages advanced technology to assess and validate the quality of vehicle repairs, specifically in Tesla vehicles. It involves using specialized equipment to perform comprehensive digital inspections, ensuring every component is accurately aligned, fastened, and functions as intended after car bodywork services or car body repair. This method goes beyond traditional visual checks, offering precise measurements and data that highlight any deviations from manufacturer specifications.

From a technical standpoint, the process integrates high-resolution cameras, 3D sensors, and powerful software algorithms to capture detailed images and create digital twins of the repaired areas. These tools enable technicians to detect even minute disparities in panel gaps, paint accuracy, and structural integrity—aspects crucial in ensuring the safety and performance of car repair services. By employing Tesla repair scanning, bodyshops can maintain consistent quality standards, reduce repairs, and ultimately deliver superior customer satisfaction.

The Role of Scanning in Post-Repair Quality Control

In the realm of Tesla repair, scanning plays a pivotal role in post-repair quality control. This advanced technology goes beyond mere diagnostics, enabling auto body shops to conduct thorough inspections and ensure that every component of the vehicle restoration meets the highest standards. By integrating Tesla repair scanning into their processes, shops can detect even the subtlest anomalies, be it misaligned panels or sensor malfunctions, which could otherwise go unnoticed.

The process involves using specialized tools to capture detailed data about the repaired vehicle, comparing it against original specifications. This digital approach enhances accuracy and efficiency in quality control, preventing subpar repairs from reaching customers. For auto body shops looking to excel in vehicle restoration, embracing Tesla repair scanning is a game-changer, fostering customer trust and ensuring every restored car meets the stringent requirements of modern automotive standards.

Benefits and Best Practices for Implementing Tesla Repair Scanning

Implementing Tesla repair scanning offers a multitude of benefits for auto body shops and repair technicians. By utilizing advanced diagnostic tools, shops can achieve unparalleled precision in their work, ensuring every component is functioning optimally after repairs or modifications. This technology allows for a deeper understanding of the vehicle’s systems, facilitating more accurate and efficient repairs, which translates to higher customer satisfaction.

Best practices for Tesla repair scanning involve integrating it into established auto repair workflows seamlessly. Shop managers should ensure technicians are well-trained in using the software effectively, as this directly impacts the quality of post-repair assessments. Regular calibration and maintenance of scanning equipment are also crucial for consistent accuracy. Additionally, promoting a culture of continuous learning among staff can help keep up with evolving Tesla vehicle technologies, maximizing the benefits of repair scanning for both the business and its customers.

Tesla repair scanning plays a pivotal role in ensuring post-repair quality control, offering a comprehensive and efficient method to verify the accuracy and integrity of repairs. By leveraging advanced technical capabilities, this process not only saves time but also enhances overall vehicle performance and customer satisfaction. Implementing Tesla repair scanning involves adhering to best practices, including thorough training, consistent standards, and regular system updates, to maximize its benefits and ensure every repair meets the highest quality benchmarks.