Tesla repair scanning is a critical process for genuine vehicle repairs and maintenance, using advanced tools to diagnose and fix issues within electrical and software systems. Adhering to OEM standards ensures compatibility, reliability, and longevity in both body repairs and services. Technicians use specialized software and hardware to access onboard computers, retrieve diagnostic codes, and conduct tests for comprehensive bodywork solutions. Staying current with OEM guidelines is crucial for auto body shops catering to Tesla owners to deliver high-quality, seamless repair experiences. Best practices include using OEM parts and tools, keeping software updated, providing proper training, conducting quality control checks, and maintaining detailed records.

Tesla repair scanning is a critical process ensuring the safety and reliability of these cutting-edge electric vehicles. This comprehensive guide delves into the essentials of Tesla repair scanning, exploring the OEM (Original Equipment Manufacturer) requirements that service centers must adhere to. We’ll break down best practices for achieving accurate results, empowering technicians with the knowledge to navigate the complex landscape of Tesla repairs efficiently and effectively.

- Understanding Tesla Repair Scanning: The Basics

- OEM Requirements for Tesla Repair Scanning

- Best Practices for Ensuring Accurate Tesla Repair Scanning

Understanding Tesla Repair Scanning: The Basics

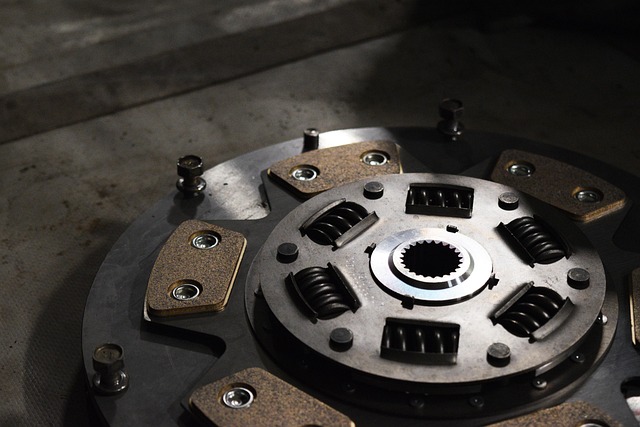

Tesla repair scanning is a critical process that forms the backbone of any genuine Tesla vehicle repair or maintenance service. It involves using advanced diagnostic tools to identify and troubleshoot issues within a Tesla’s complex electrical and software systems. These systems control everything from the car’s engine and drivetrain to its infotainment and driver-assistance features, making accurate scanning essential for ensuring both safety and optimal performance.

At the heart of this process lies the original equipment manufacturer (OEM) standards that guide how repairs should be conducted. Adhering to these standards is paramount because they guarantee compatibility, reliability, and longevity in vehicle body repair and automotive repair services. When performing Tesla repair scanning, technicians utilize specialized software and hardware tools to access the car’s onboard computer systems, retrieve diagnostic codes, and run tests. This data not only helps pinpoint problems but also provides insights into potential underlying issues within the car’s circuitry or software, allowing for more comprehensive car bodywork services when needed.

OEM Requirements for Tesla Repair Scanning

When it comes to Tesla repair scanning, understanding Original Equipment Manufacturer (OEM) requirements is paramount for any reputable auto body shop or auto body repair service. These standards ensure that repairs are both safe and reliable, maintaining the vehicle’s original performance and aesthetics. For instance, Tesla employs advanced diagnostic tools and software that auto body shops must be equipped to access, enabling them to accurately identify and rectify issues within the electric vehicles’ complex systems.

OEMs like Tesla set specific guidelines for scanning procedures, including the use of certified equipment and trained technicians. Auto body services that cater to Tesla owners must stay current with these requirements to guarantee accurate diagnostics. This process involves more than just replacing parts; it entails precise coding, recalibration, and retesting to meet OEM standards, ensuring a seamless and secure repair experience for electric vehicle owners.

Best Practices for Ensuring Accurate Tesla Repair Scanning

To ensure accurate Tesla repair scanning, several best practices should be followed. Firstly, use only OEM (Original Equipment Manufacturer) parts and tools for the most precise results. This includes specialized diagnostic equipment that aligns with Tesla’s standards, as using generic or non-OEM components can lead to inaccurate readings and subpar repairs.

Additionally, maintain regular updates on software and firmware for your scanning tools to capture the latest vehicle data. Proper training for technicians is paramount; ensure they are certified and well-versed in Tesla repair procedures, including any unique coding or programming required for specific models. Consistent quality control checks and double-checking of scans by experienced technicians further safeguard against errors. Lastly, keep detailed records of all scans and repairs for future reference, facilitating efficient auto maintenance and ensuring the longevity of your Tesla’s performance.

Tesla repair scanning is a critical process that ensures vehicles return to their optimal performance and safety standards. Understanding OEM requirements and adhering to best practices is essential for accurate repairs, fostering customer satisfaction, and maintaining Tesla’s high-quality reputation. By embracing these guidelines, automotive professionals can navigate the complex landscape of Tesla vehicle diagnostics with confidence, ultimately revolutionizing the way we approach electric car repairs.